Quality Audits for ISO 13485

Specifically created for the manufacture of medical devices, ISO 13485:2016 is a management systems standard that is based on the ISO 9001 process model methodology. Its main goal is to make it easier to comply with standardized medical device regulatory criteria.

This standard enables businesses to eliminate legal and safety hazards while establishing more cost-effective workplaces. Having ISO 13485 certification aids organizations in being seen as more reliable, trustworthy providers because it is an internationally recognized standard of quality and safety for the manufacturing of medical devices.

Medical Device 13485

Service Codes

NAICS Codes

611430 – Professional and Management Development Training

541614 – Process, Physical Distribution, and Logistics Consulting Services

921190 – Other General Government Support

PSC Codes

H151 – Quality Control- Hand Tools

H152 – Quality Control- Measuring Tools

R704 – Support- Management: Auditing

UNSPSC Codes

81141510 – Quality control and quality assurance audit and verification services

84111600 – Audit services

81111819 – Quality assurance services

81141500 – Quality control

81141510 – Quality control and quality assurance audit and verification services

81141511 – Quality control and quality assurance consultancy services

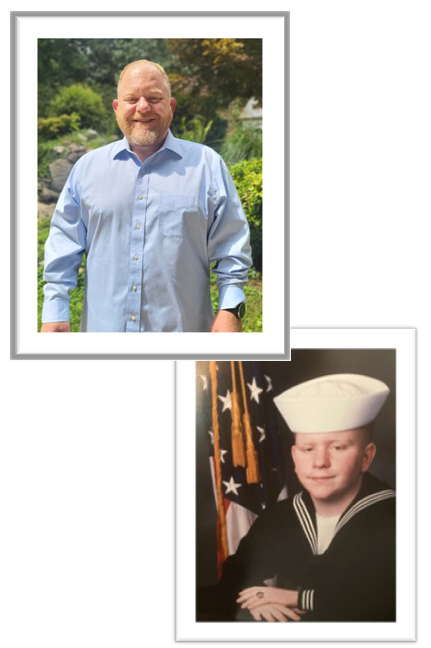

About David Jung

Owned and Operated by a Service Disabled Veteran, David Jung founded Resource Overwatch in 2021 after 20+ years of working within multiple industries. His experience working overseas with multinational companies has given him a unique insight into how companies can create and maintain advantages based on their resource management.

David comes from 3 generations of veterans. After honorably serving a four-year commitment, David completed his bachelor’s degree and started working in manufacturing. Over the past 20+ years, he has worked with large fortune 500 companies and small 100-person companies.

Commitment to this country, the community, customers, suppliers, and partners he works with are the founding principles upon which Resource Overwatch was founded

He has channeled these qualities into our company’s mission—dedication to our customers resource needs, a stable and vast sourcing network, excellence in supply chain management, premier customer service, and a focus on giving back to the community.

The 5 Key Elements of ISO 13485

Whether you need a compelling video written, filmed, or edited or a compelling website page designed and developed, Resource Overwatch has the experience and talent to deliver.

For manufacturers of medical devices, ISO 13485 specifies requirements for design and development, risk management, production, and post-production procedures. The following five standards from ISO 13485 are crucial for businesses looking to be certified:

- Quality Management System (QMS)

- Management responsibility for implementation and maintenance

- Resource management to meet regulatory and customer requirements

- Product planning and realization

- Monitor, measurement, analysis, and improvement processes

Our Core Quality Audit Services

A Service Disabled Veteran Owned Small Business (SDVOSB)

General Manufacturing ISO 9001

Ultimate global benchmark for quality management

- Reduce operating costs

- Improve efficiency

- Continual improvement

- More satisfied customers

Automotive IATF 16949

Common automotive quality system requirement based on ISO 9001

- Continuous improvement

- Defect prevention

- Reduction of variation

- Reduction of waste

Aerospace AS9100

Standard for aviation, space and defense products

- Improved stakeholder relations

- Enhanced process effectiveness

- Reduced operating costs

- Supply chain access

Environmental ISO 14001

Helps control the impact of activities on the environment.

- Helps with governmental compliance

- Reduces environmental impact

- Helps meet environmental objectives

- Fulfills compliance obligations

Safety ISO 45001

Create a culture of health and safety

- Proactive risk prevention

- Increase organizational resilience

- Strengthen legal and regulatory compliance

- Innovate and continually improve

Medical Device 13485

Manages quality throughout medical device life cycle

- Manage risk

- React to changing regulatory environment

- Improves controls

- Effective product traceability

Lab 170025

For more consistent operations and processes

- Control records

- Addresses risks and opportunities

- Reduce errors

- Adherance to policies

What is ISO 13485 and why quality audit for it?

The medical device sector has its own international standard for quality management systems called ISO 13485. It provides the specifications for medical device design, development, production, installation, and maintenance, as well as associated services. Organizations can use ISO 13485 and should perform ISO 13485 quality audits to ensure adherence to its standards.

The following are some essentials concerning ISO 13485:

System for Managing Quality (QMS): An organizational QMS can be established and maintained using the framework provided by ISO 13485. In order to guarantee the security and efficacy of medical devices, the standard highlights the significance of risk management, process control, and documentation.

Regulatory conformity: ISO 13485 assists organizations in meeting the quality system criteria of several regulatory agencies, including the European Union’s Medical Device Regulation (MDR) and the U.S. Food and Drug Administration’s (FDA).

Continuous Improvement: The standard necessitates the development of procedures for tracking and evaluating product performance, client comments, and internal auditing operations.

Risk Management: Organizations must set up procedures for locating, evaluating, and reducing risks related to their goods. ISO 13485 and quality audits for ISO 13485 entails locating hazards, calculating risks, putting risk control strategies into action, and assessing how well they work.

Supplier Control: ISO 13485 and quality audits for ISO 13485 emphasize the significance of supplier control and calls on businesses to set standards for choosing and assessing their suppliers. It highlights the need of maintaining open lines of contact with suppliers and making sure they adhere to the essential quality standards.

Documentation and record keeping: ISO 13485 places a strong emphasis on keeping track of design and development work, manufacturing procedures, quality control checks, and post-market work including customer complaints and product recalls.